Introduction

In the competitive realm of plant extraction, achieving the ideal consistency is paramount for ensuring quality and satisfying consumers. Badder, recognized for its creamy texture and rich flavors, has gained immense popularity among connoisseurs. One cutting-edge solution that can elevate the production of badder is the STP-3000. This article delves into how a planetary centrifuge can streamline the process of creating badder extract and take the strain out of manual labor.

What Exactly is Badder?

Badder is a concentrate celebrated for its thick, butter-like texture. It is produced through a combination of extraction and agitation processes, which work together to achieve a smooth and uniform product. Employing the right post-processing technique is vital for obtaining the desired badder consistency.

The Function of a Planetary Centrifuge

The STP-1500 is a specialized device designed to harness centrifugal and shear forces for material homogenization and the removal of unwanted residual LPGs. Regarding plant extraction, it excels in refining the consistency of badder by effectively blending, aerating, or deaerating the extract.

Utilizing the Centrifuge for Solvent Removal

The Mechanics of a Planetary Centrifuge

The innovative design of a planetary centrifuge facilitates the thorough blending of extracts. As the container rotates, it spins in the opposite direction of the centrifuge's axis, creating a tumbling effect that optimizes product mixing. For creating a dab-worthy badder consistency, consider these insights:

- Cultivating certain THCA levels and ensuring sufficient terpenes present can enhance the whipping effect.

- Retaining a bit of solvent can contribute to cooler temperatures via evaporative cooling, further optimizing the process.

Advantages of a Planetary Centrifuge in Badder Extraction

- Uniformity: With precise control over rotational speeds, time, and vacuum levels, a planetary centrifuge ensures a consistent badder texture, minimizing the risk of separation or graininess.

- Efficiency: The rapid operation of a planetary centrifuge can drastically cut down processing time, reducing the need for extensive manual labor in post-processing.

- Quality Improvements: By eliminating impurities and ensuring an even texture, the resulting product boasts higher quality and remains homogenized during storage, attractive to consumers looking for premium concentrates.

Conclusion

Integrating a planetary centrifuge into the badder extraction workflow can transform how producers manufacture this in-demand concentrate. By enhancing consistency, boosting efficiency, and elevating product quality, this technology is revolutionizing the plant extraction landscape. As consumer demand for top-notch badder continues to rise, embracing advanced equipment like a planetary centrifuge will be critical for maintaining a competitive edge.

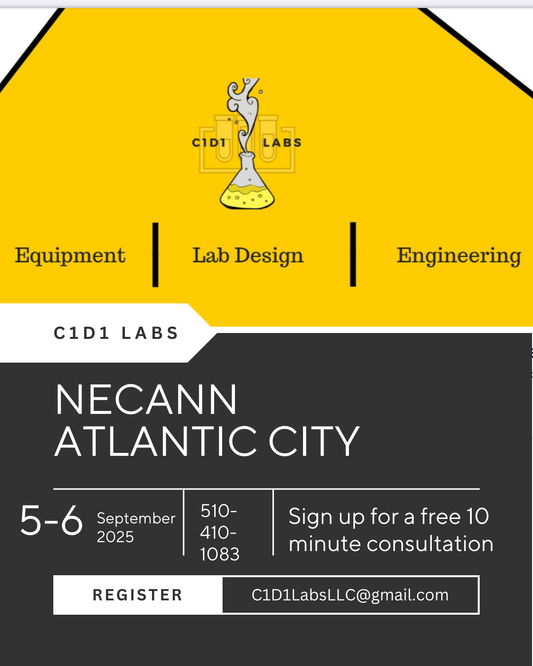

Connect With Us Today

For producers seeking to refine their extraction methodologies and achieve that perfect badder consistency, investing in a planetary centrifuge is the key to excellence. Discover the opportunities this technology presents and elevate your product line! Reach out to us at 510-410-1083.